Note:

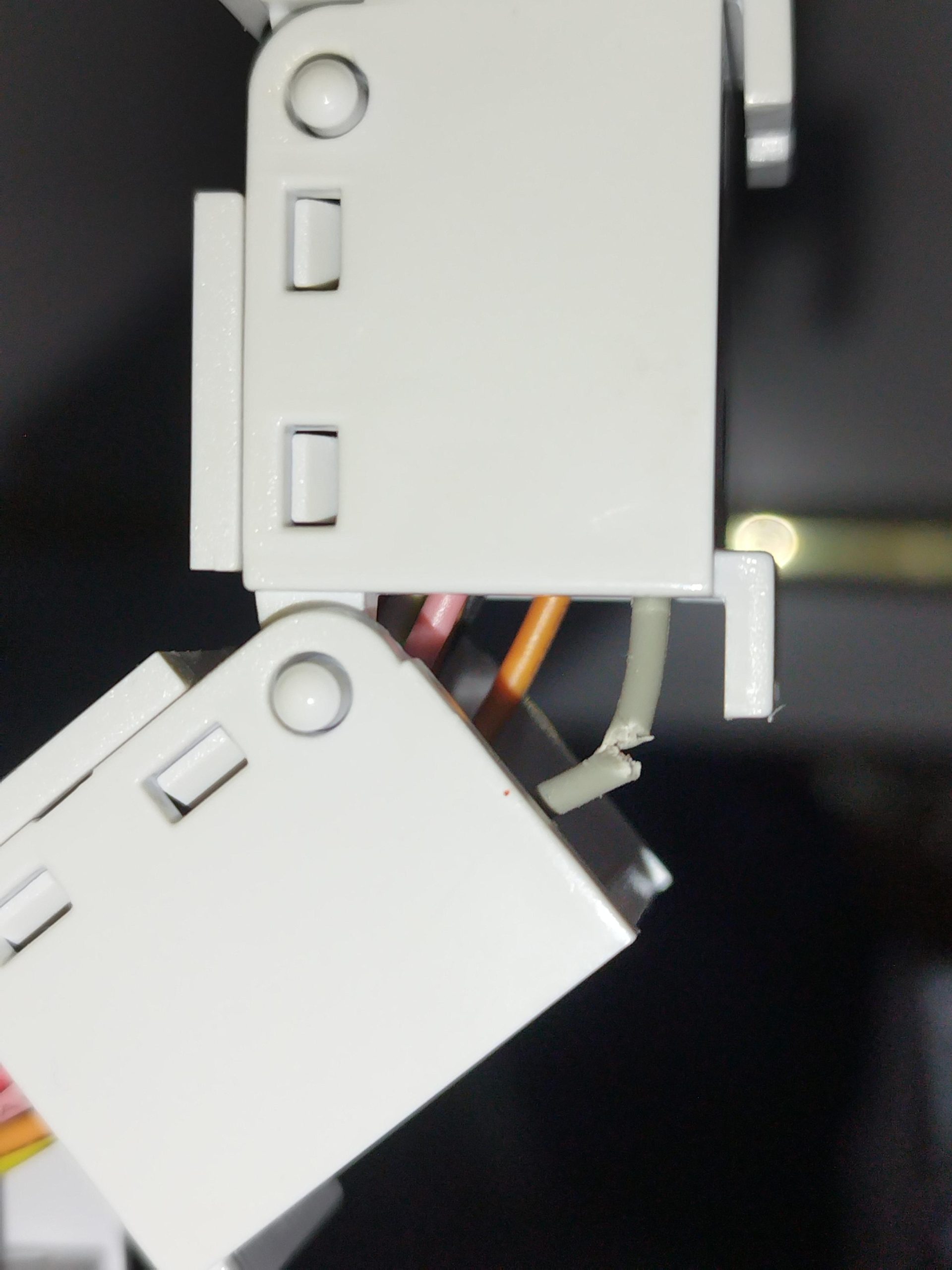

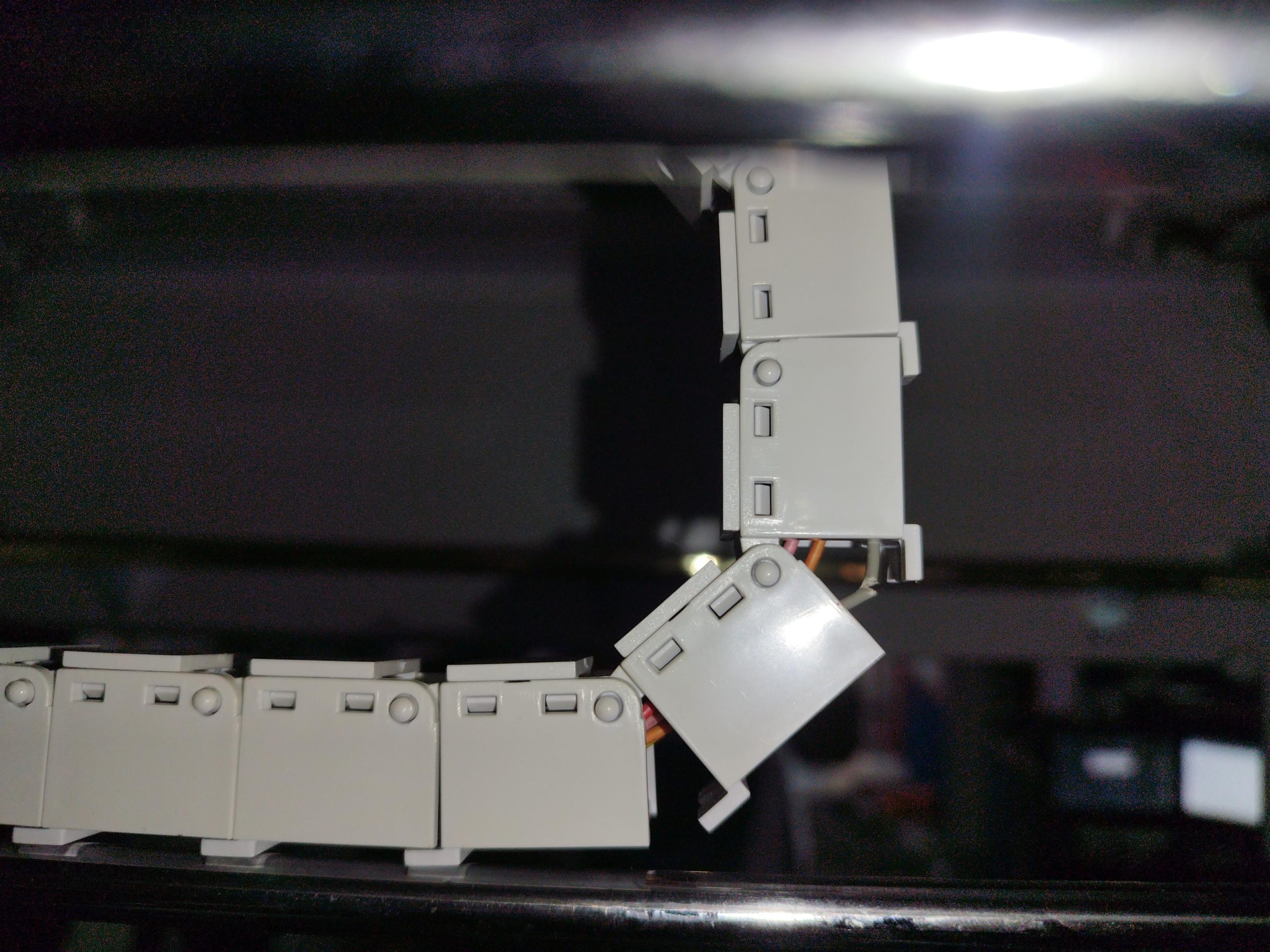

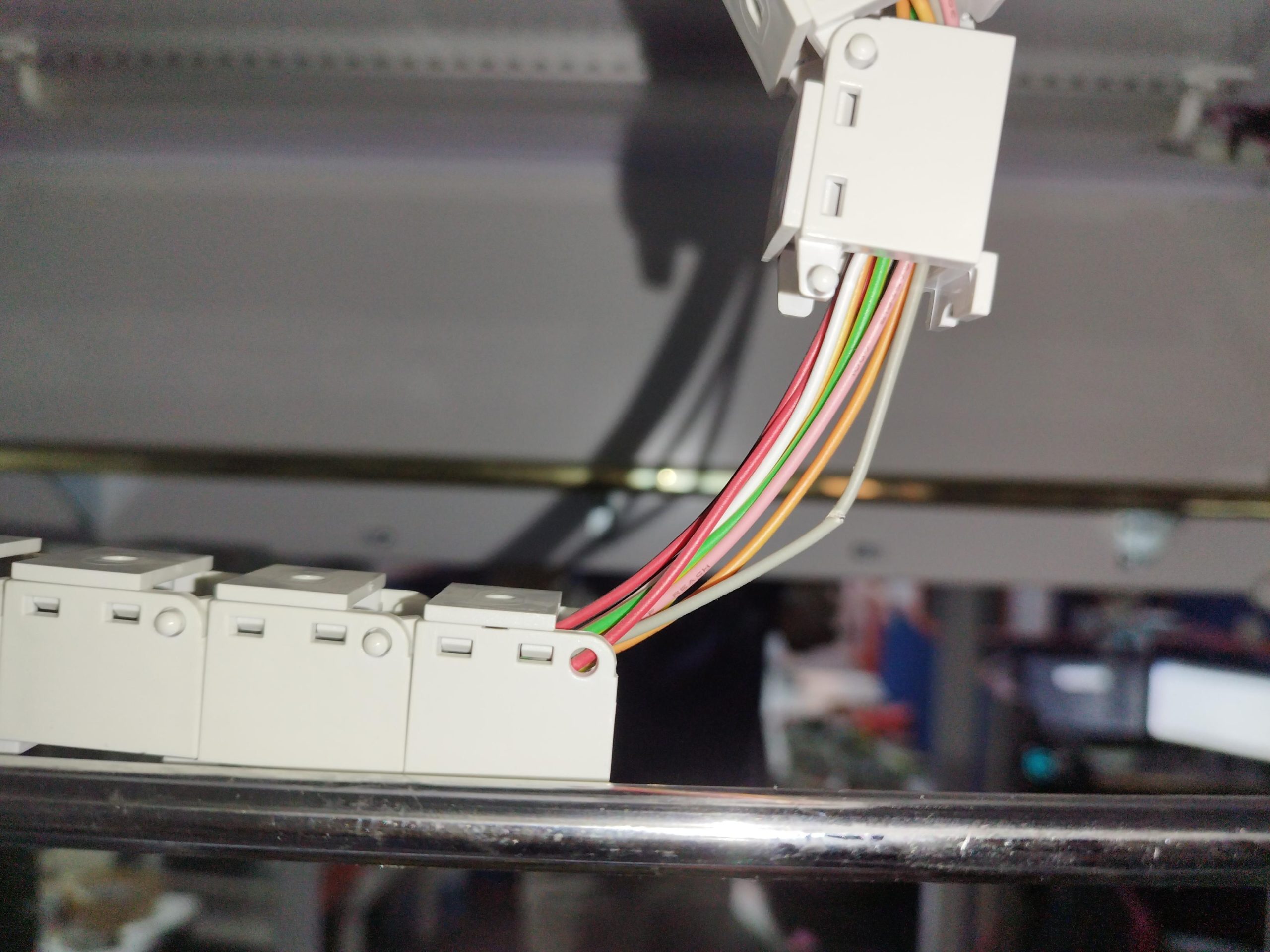

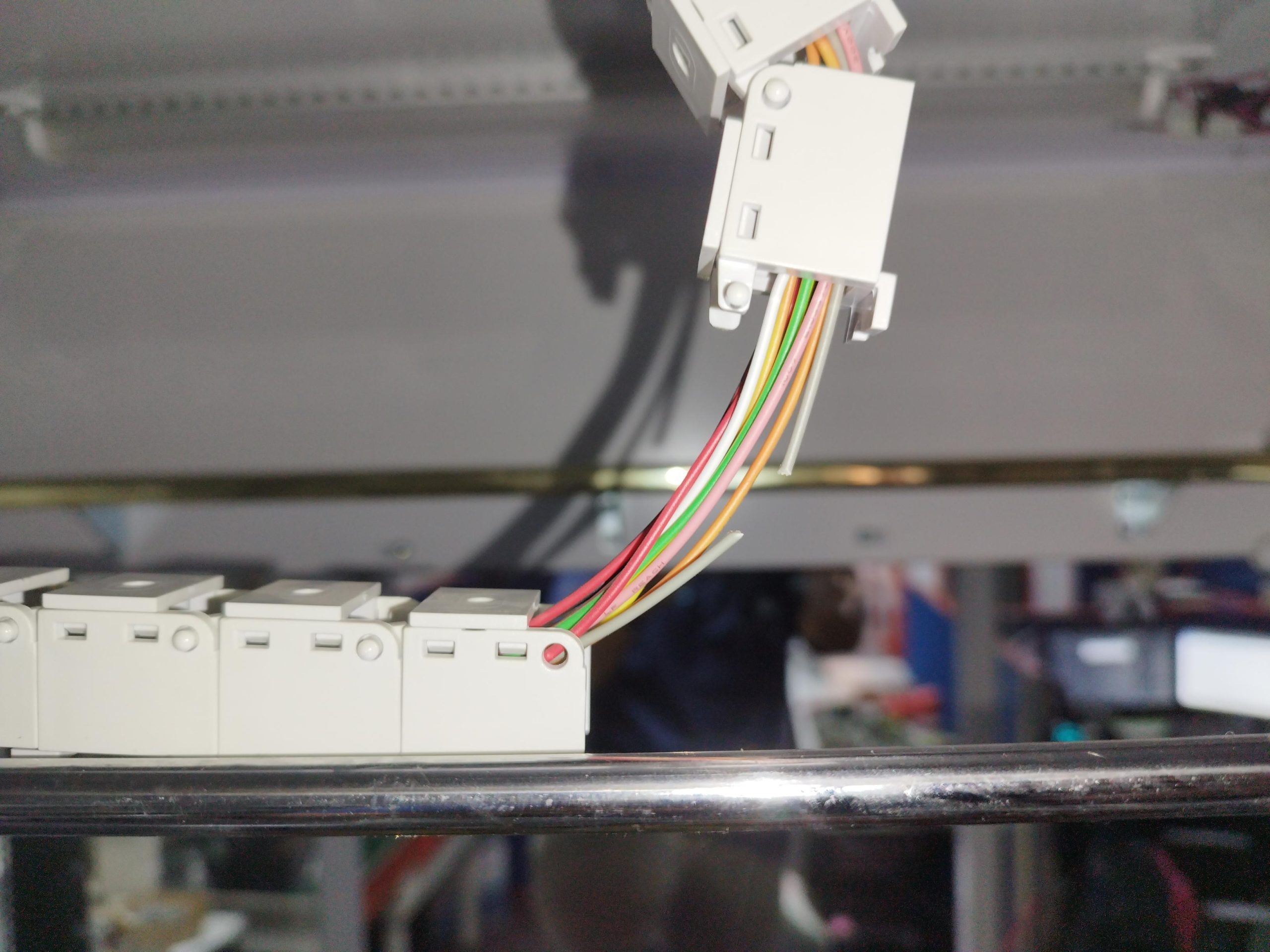

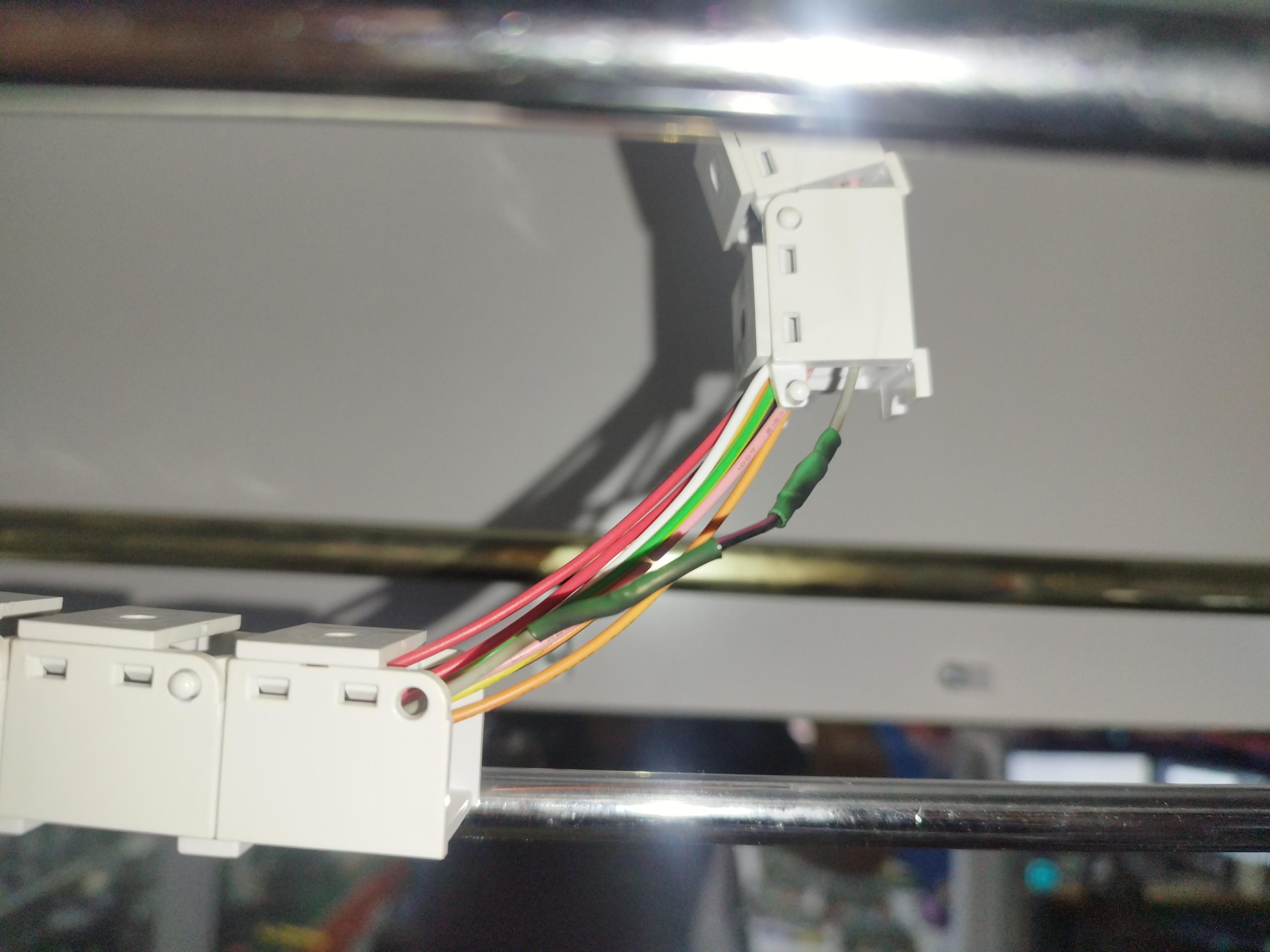

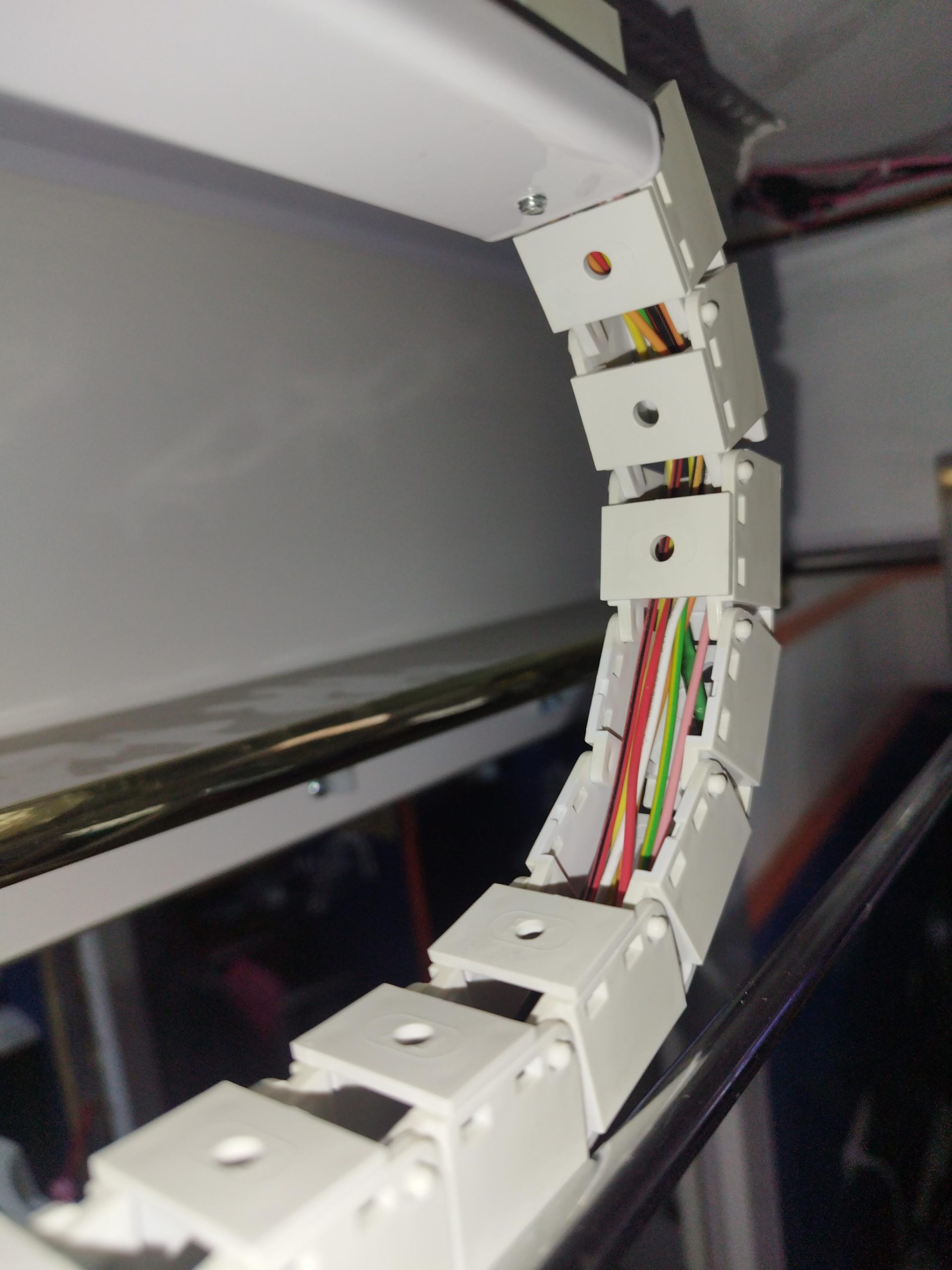

Breaks can be a clean snap or might just be a bend or kink in a wire. Look for discoloration too as it might show straining on the plastic or brittle wires.

Step 1:

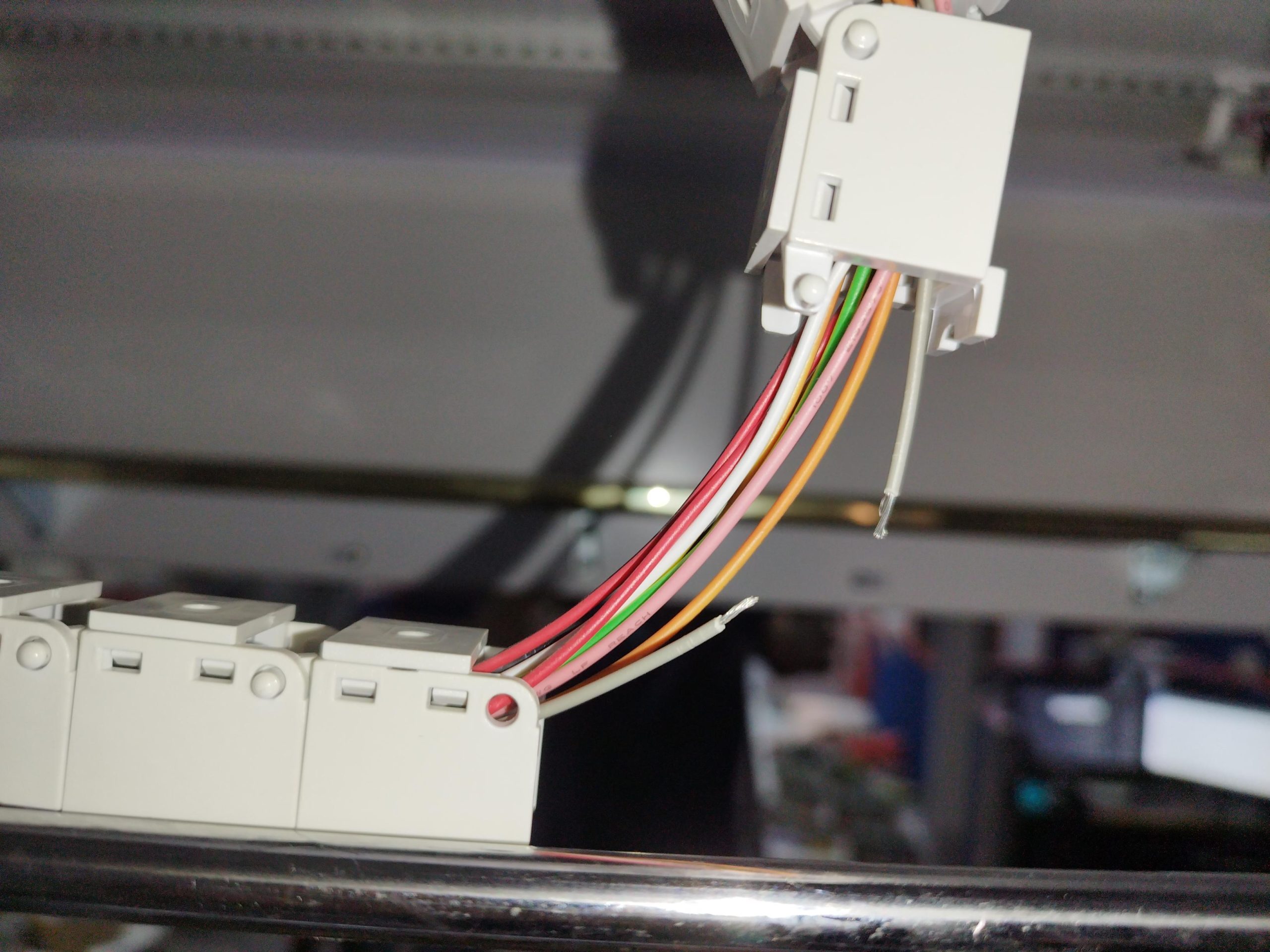

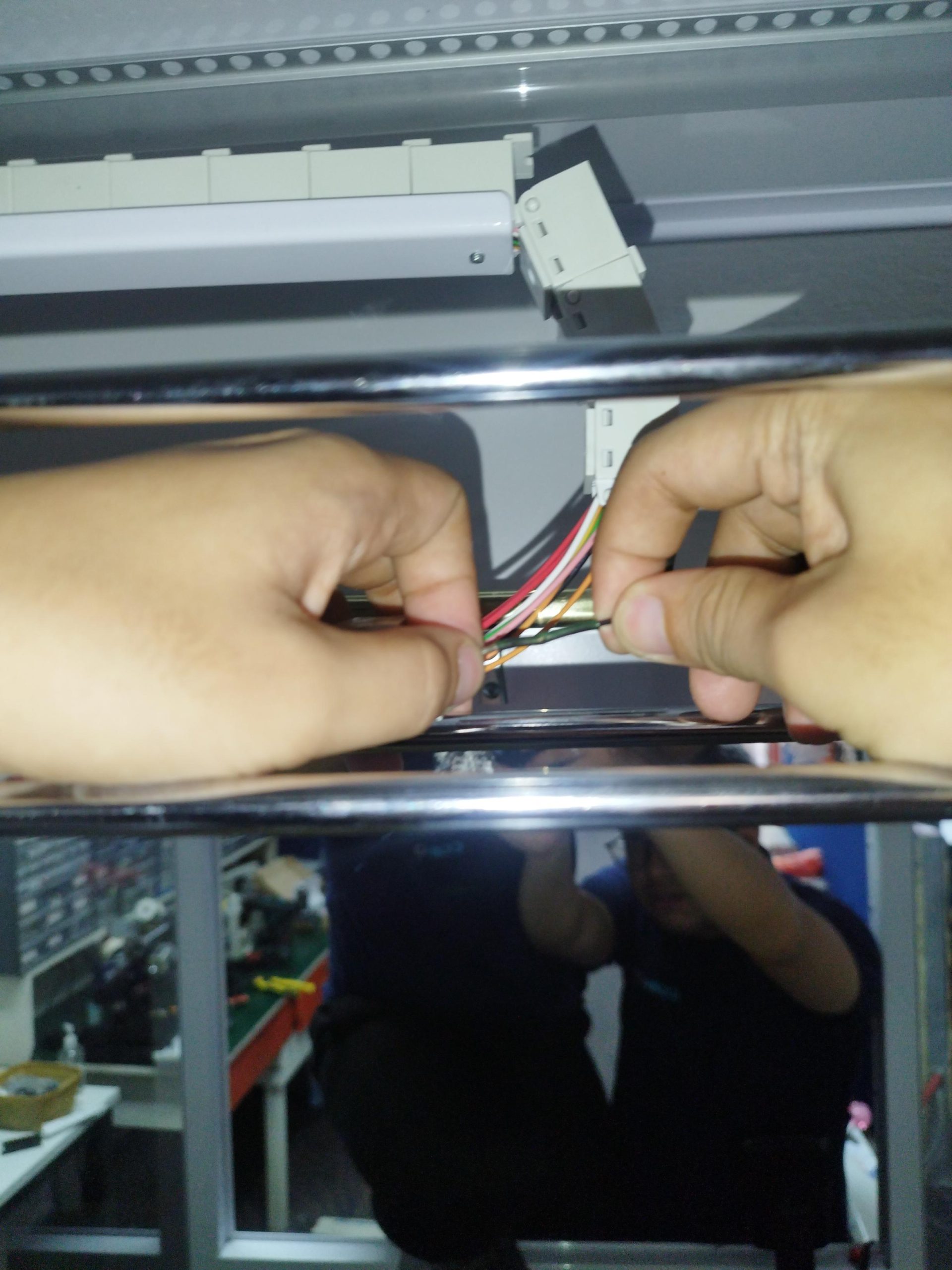

Remove 4-5 caterpillar clips from the loom you want to check. If the wiring is fine underneath, then move the clips from the next area you want to check and cover the area just checked. Repeat on both looms until the problem is found.

Step 2:

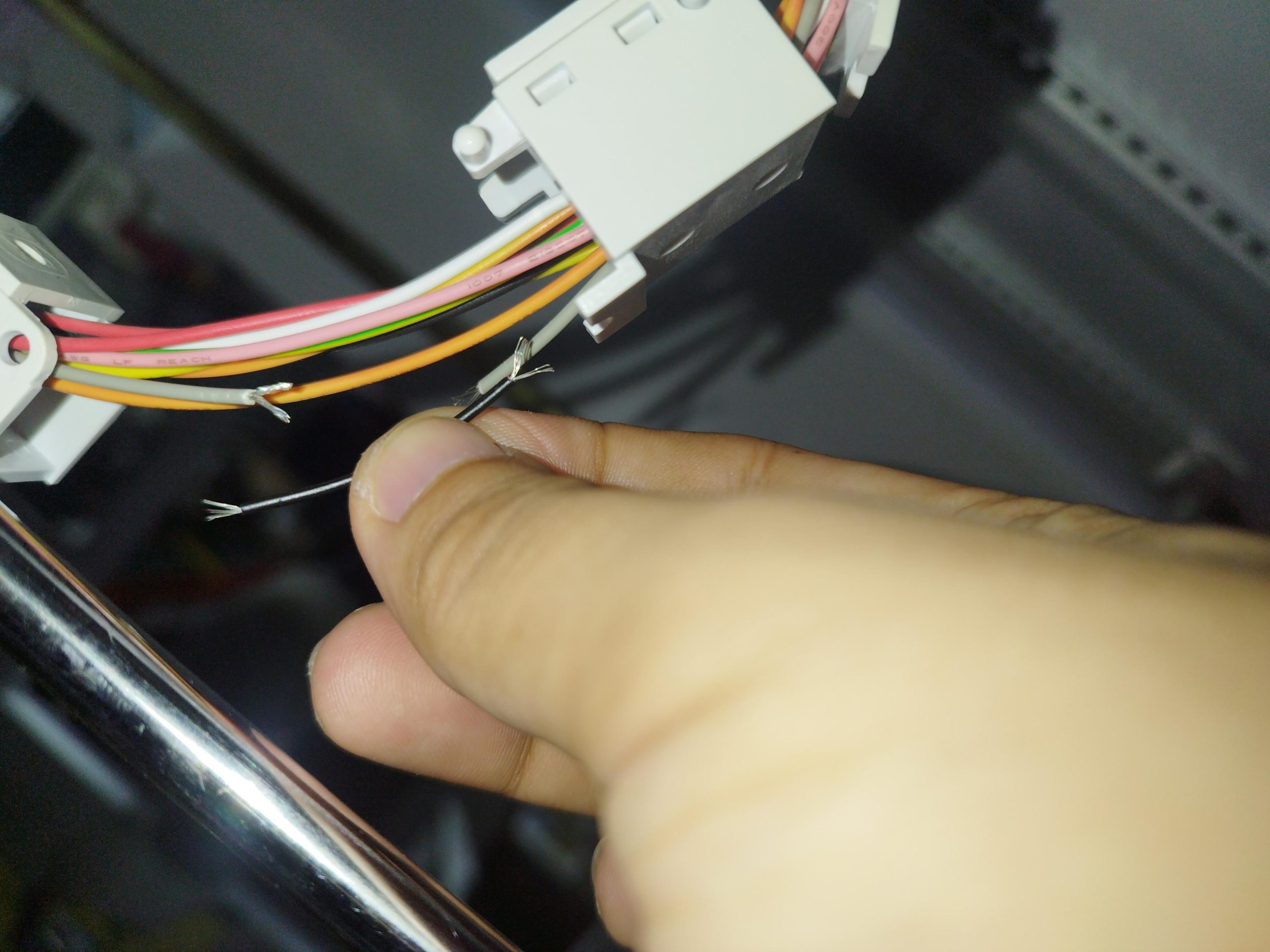

Once the issue is located, snip an inch off each side of the break to make sure the repair area is not frayed or damaged wiring then strip the ends.

Step 3:

Measure out a new piece of wiring a little longer than the distance between the two original wire ends, too short and it will end up pulled apart again so needs a little extra length.

Step 4:

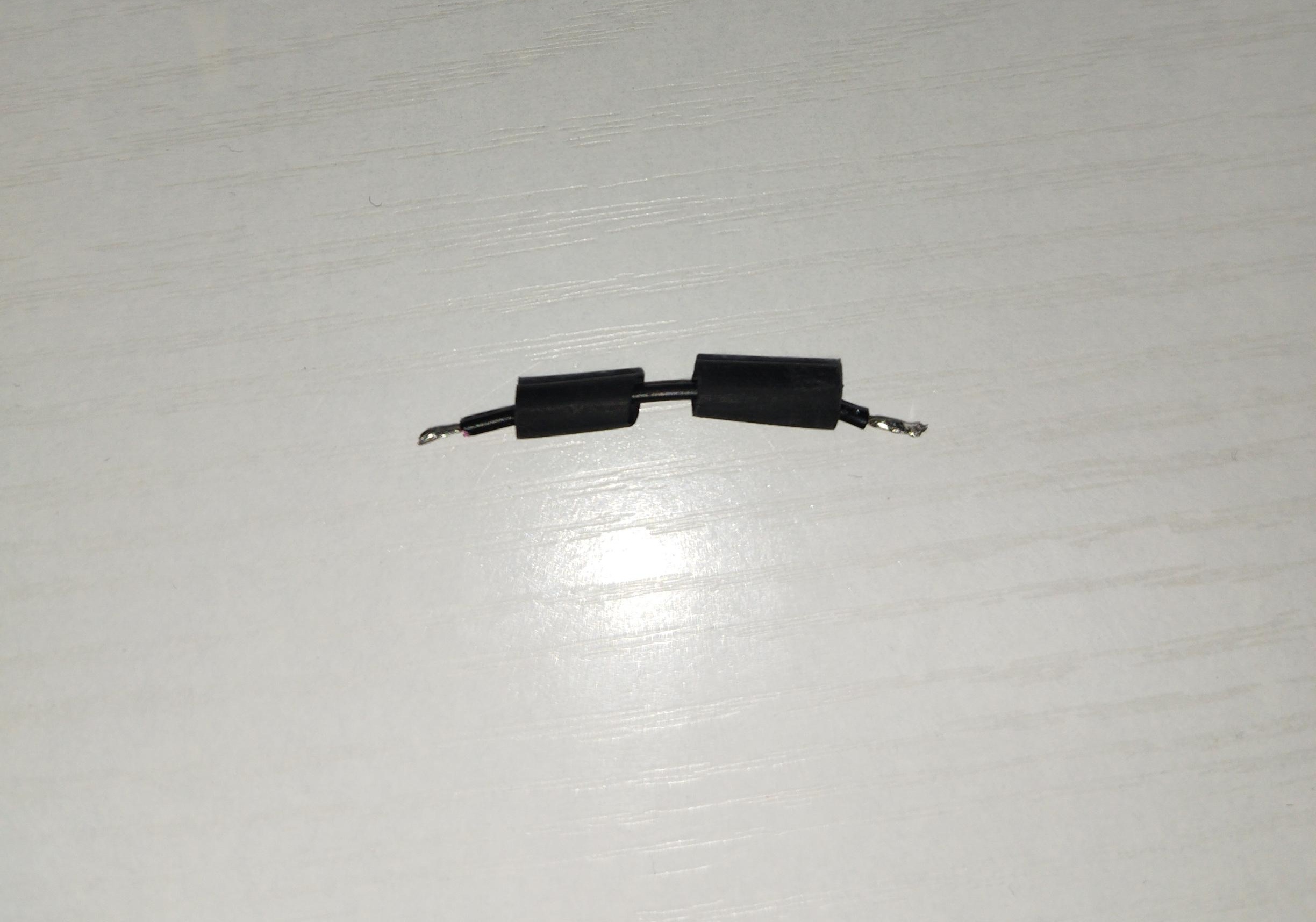

Strip each side of the new wiring, if heat shrink is being used then slip it onto the wire before you fan out or connect the two sides.

Step 5:

Gently fan out the inner wiring of both the new wire and the loom.

Step 6:

Interlink the two fanned ends to the base of the plastic and twist tightly.

Step 7:

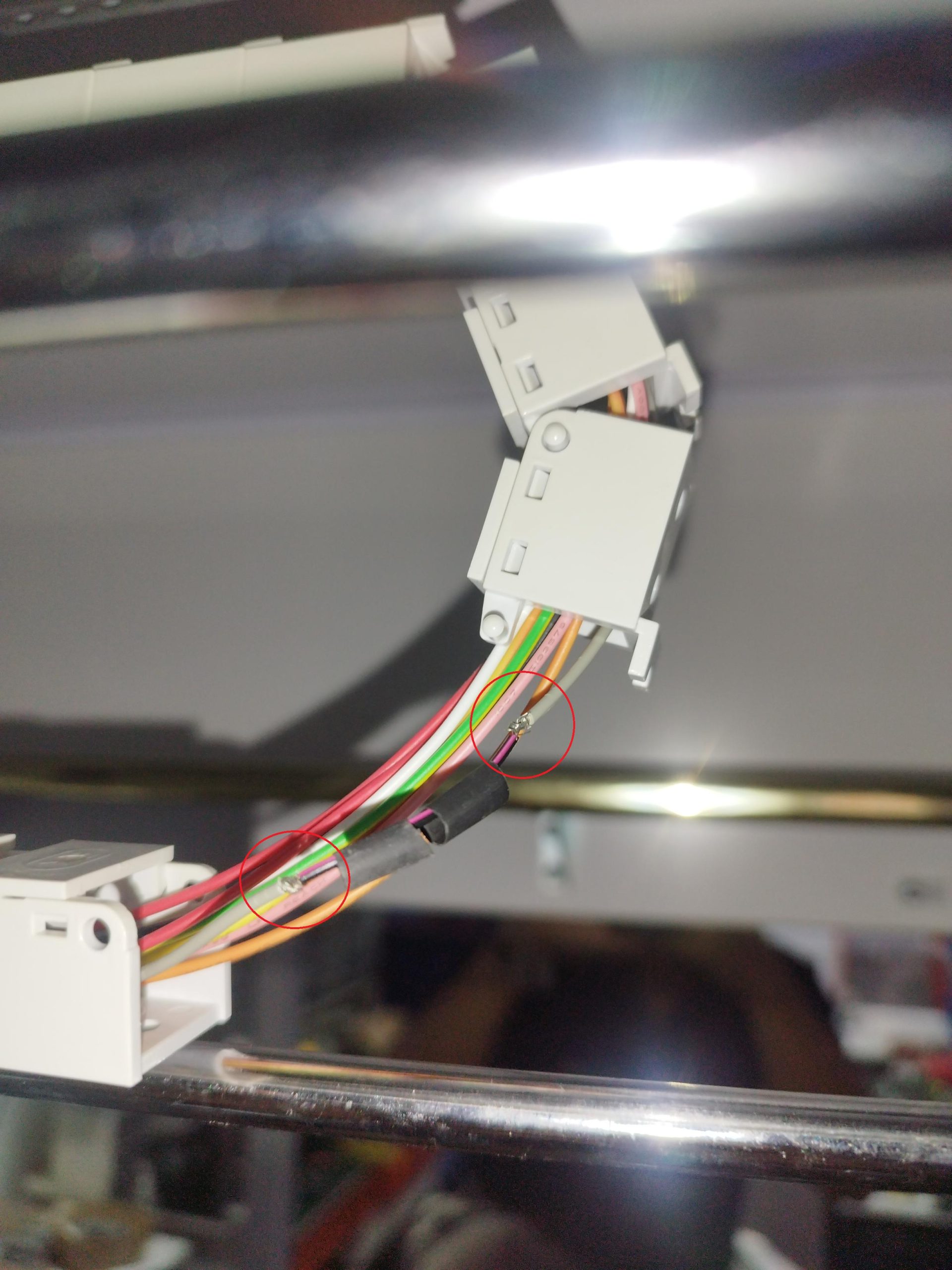

Bend the interlinked wire to one side over the wire and bring the heat shrink over.

Step 8:

Ensure all metal is covered by the heat shrink before using a lighter at a distance to seal the repair without burning the wire.

Step 9:

Give a slight pull on the wire to check they are not going to pull apart and then repeat for the other side.

Step 10:

Once both sides are done return the caterpillar clip BOTTOMS to the correct locations and test the machine.

Step 11:

Once the repair has been confirmed to have fixed the issue then put the tops back on the caterpillar clips.